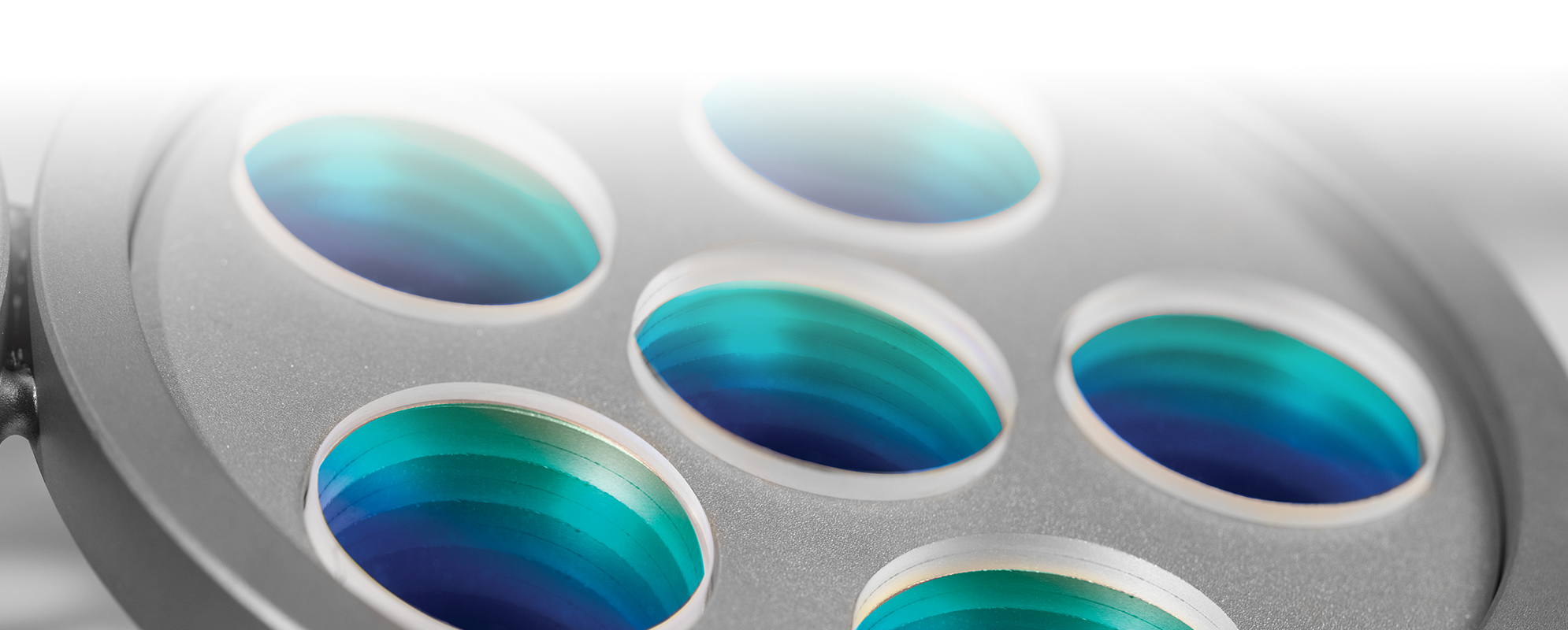

Whether you need high laser damage threshold coatings, tightly-toleranced laser optics substrates, optical components, or laser assemblies, we have the expertise and state-of-the-art equipment to make and measure the laser optics required for your application. Contact our experienced laser optics engineers to inquire about tighter specifications than those shown in the tables below.

Build-to-print and fully-custom design

Manufacturing from prototyping to volume production

Complex coatings: high laser damage threshold, multi-band anti-reflective, highly-reflective, partially reflective, or ultrafast

Anti-reflective coatings for wavelengths from 248nm – 12µm and highly-reflective wavelengths from 248nm – 40µm

State-of-the-art metrology utilized to consistently meet specifications

Edmund Optics® engineers have the expertise to guide you through selecting the best coating technology for your application. Lead times are as fast as two weeks for standard coatings.

Sample Coating Curves

These coating curves are not an exhaustive summary of capabilities, but they show some examples of the coatings designed by Edmund Optics®.

Electron-Beam (E-Beam) Coatings

Low-stress, cost-effective coatings ideal for many laser optics

Ion-Assisted Deposition (IAD) E-Beam Coatings

Versatile coating technology achieving higher density and more environmentally stable coatings

Ion Beam Sputtered (IBS) Coatings

Highly-repeatable, highly-environmentally-stable technology ideal for high reflectivities, ultrafast optics, and filters with sharp transitions

Magnetron Sputtering

Low chamber pressure reduces setup time and allows for more economical coating of high-volume optics

| Optical Coating Capabilities | |

|---|---|

| Specification | Value |

| Dimensions | 2 – 457.2mm |

| Clear Aperture | Up to 100% (Dependent on Substrate Dimensions / Geometry / Tolerances) |

| Reflectivity | 0.05 – 99.99% (ppm-level losses on request) |

| Anti-Reflective Wavelength Range | 248nm – 12µm |

| Highly-Reflective Wavelength Range | 248nm – 40µm |

| Laser Damage Threshold (LDT) for ns pulses | >40 J/cm2 @ 1064nm, 20ns, 20Hz Pulses |

| Laser Damage Threshold (LDT) for ultrafast fs pulses | >0.3J/cm2 @ 800nm, 48fs, 100Hz Pulses, Guaranteed >0.7 J/cm2 @ 800nm, 200fs, 100Hz >0.4 J/cm2 @ 1030nm, 200fs, 100Hz >0.9 J/cm2 @ 1030nm, 500fs, 100Hz |

| Group Delay Dispersion (GDD) Range | -4000 – 5000 fs2 |

| Durability | MIL-PRF-13830B APP C, PARA C.3.8.4, PARA C.3.8.5, MIL-C-48497A |

| Shortpass Filter Cut-Off Wavelength | 400 – 1600nm |

| Longpass Filter Cut-On Wavelength | 240 – 7300nm |

| Bandpass Filter CWL, OD, and Bandwidth | 193 – 10,600nm, >OD 7, 1nm - Broadband |

| Notch Filter CWL | 355 – 1064nm |

| Reflective ND Filter OD | OD 0.1 – OD 3 |

| Filter Center Wavelength (CWL) Tolerance | ±1nm |

| Filter Edge Tolerance | <1% Deviation, <0.2% Special Cases |

| Beamsplitter (BS) Wavelength Range | 240 – 20,000nm |

| BS Polarization Extinction Ratio (S:P) | 10,000:1 |

Mirrors, windows, filters, and thin-film polarizers in a wide variety of substrate materials

| Flat Optic Capabilities | |

|---|---|

| Diameter | 5 - 200mm |

| Dimensional Tolerance | +0/-0.010mm |

| Thickness | ±0.010mm |

| Clear Aperture | >90% |

| Surface Flatness (P - V) | λ/10 to λ/20 |

| Bevel (face width @ 45 degrees) | <0.25mm |

| Surface Quality | 10-5 |

| Parallelism | <10 arcsec |

| Materials | UV Grade Fused Silica (Corning HPFS® 7980), KrF Grade Fused Silica (Corning HPFS® 7980), IR Grade Fused Silica (Corning HPFS® 7979), Sapphire, N-BK7, N-SF5, N-SF11, CaF2, and More |

| Surface Roughness | 10 - 15Å typical, <1Å for superpolished surfaces |

Aspheric, spherical singlet, and achromatic lenses designed for specific laser wavelengths

| Lenses Capabilities | |

|---|---|

| Diameter | 5 - 200mm |

| Diameter Tolerance | +0/-0.010mm - +0/-0.025mm |

| Asphere Figure Error (P - V) @ 633nm | 1λ |

| Vertex Radius (Asphere) | ±0.1% |

| Peak Slope Error | 0.35μm/mm per 1mm window |

| Centering (Beam Deviation) | 1 arcmin |

| Center Thickness Tolerance | ±0.050mm |

| Surface Quality (Scratch Dig) | 10-5 |

| Aspheric Surface Metrology | Profilometry (3D) |

| Surface Roughness (RMS) | 2nm |

| Thickness | ±0.010mm |

| Power (P - V) | λ/2 |

| Irregularity (P - V): | λ/40 |

Crystal cutting, grinding, polishing, coating for high LDT and throughput, and refurbishing

| Laser Crystal Capabilities | |

|---|---|

| Dimensional Tolerance | ±0.1mm |

| Form Factors | Rod, rectangular, and zigzag |

| Clear Aperture | 90% of Diameter |

| Surface Quality | 10-5 |

| Parallelism of Polished Surfaces | <10 arcsec |

| Parallelism of Tilted Ends | <3 arcmin |

| Perpendicularity | <5 arcmin |

| Surface Figure | λ/10 at 632.8nm Over the Clear Aperture |

| Protective Chamfer | Not to Encroach on the Clear Aperture |

| Materials | Can Fabricate and Coat: Nd:YAG, Er:YAG, CTH:YAG, Nd:YLF, Tm:YLF, Ba:YLF, Cr:LiSAF, KTP, RTP, RTA, Alexandrite, ZGP, Cr:ZnSe, Fe:ZnSe, Nd:YV04, TGG, LiNbO3, PPLN, and MgO:PPLN |

| Can Only Coat: Cr:YAG, Yb:KGW, LBO, and BBO | |

Wide variety of prism shapes and substrates with optical contacting available for high-power beam steering applications

| Prism Capabilities | |

|---|---|

| Dimensions | 2 – 75mm |

| Dimensional Tolerance | +0/-0.01mm |

| V-Height | >±0.03mm |

| Irregularity | λ/20 |

| Prism Physical Angle Tolerance | ±0.5 arcsec |

| Max Bevel (Face Width @ 45°) | ±0.05mm |

| Surface Quality (Scratch Dig) | 10-5 |

| Bonded Prism Assembly Beam Deviation | 0.5 arcmin |

Shop our Marketplace for the world’s largest selection of off-the-shelf optical components with same-day shipping.

4 week lead time for modifying wavelength or threading on standard beam expanders, objectives, f-theta lenses, and other laser optics subassemblies

Design and manufacturing capabilities for custom beam expanders, focusing objectives, and other laser optics subassemblies

Active alignment and centration for advanced assemblies

High-power assemblies designed without internally-focusing ghost images

Full assembly development from modeling physical optics propagation, to designing lens elements, to coating, to assembly, to testing

| Beam Expander Capabilities | |

|---|---|

| Expansion Power | >1X - 20X |

| Design Wavelengths | Common Laser Lines Including Nd:YAG, Yb:YAG, Ti:sapphire, and Tm/Ho-Doped Fiber Lasers, Broadband |

| Mounts | C-Mount, M22, M30, Custom |

| Focusing Mechanisms Available | Sliding Optics, Rotating Optics, Fixed |

| Testing/Design Specifications | Transmitted Wavefront Error, Power in the Bucket / Energy on Target, Focused Spot Size |

| Assembly Size | >20mm - 1m |

| Ruggedization Available | Athermalization, Shock and Vibration, Sealing from Contaminants |

Transfer from concept to volume manufacturing

Expedited prototyping

Cleanroom assembly

Active alignment and centration

Testing and certification

In-house testing to measure assembly performance

Transmitted wavefront error, laser beam profiling, and beam caustics

Development of application-specific tests

Shop our Marketplace for the world’s largest selection of off-the-shelf optical components with same-day shipping.

Edmund Optics® designs and deposits highly-reflective and anti-reflective coatings for ultrafast lasers as well as ultrafast-enhanced silver coatings.

Full custom design of coatings and components

Highly-flexible volume order servicing

Competitive volume pricing

Dedicated engineering support personalized for your needs

Reflectivities >99.99% (ppm-level losses on request)

Coatings that are more environmentally stable in varying temperature and humidity conditions

Coatings covering wavelengths between 355-1600nm

Group delay dispersion (GDD) control for ultrafast coatings

Minimize scatter losses with ultra-low surface roughness

RMS surface roughness <1Å

Standard sizes and shapes from 12.7 to 50.8mm

Custom sizes and shapes upon request

Supported by a suite of in-house metrology

Parts-per-million level scattering

In-house laser lab performing long-run applied UV laser exposure experiments at 355nm with a 10ns pulse duration

Laser-induced contamination is a key concern for UV laser systems

Contamination resulting from the environment or outgassing can significantly reduce performance or lead to system failure

Intimate knowledge of cleaning and assembly techniques to mitigate these effects

Supported in-house testing for transmitted wavefront error, power in the bucket, energy on target, and focused spot size

Actively compensate for the decenter and tilt of optical components during assembly

Critical for precision objectives, beam expanders, and other assemblies

4 ISO Class 6 clean rooms for assembly and a Class 7 cleanroom for incoming inspection

Laser crystal and doped glass grinding, polishing, and coating in sizes from 2 – 457.2nm

Over 30 years’ experience with coating adhesion and durability for laser optics

Also refurbish both flat and curved laser rods, preventing you from waiting to source whole new rods

Our metrology lets us guarantee centration and radius of curvature

Use our Quote Request Form to upload a drawing for quote

or fill out the General Request Form below to get in touch.