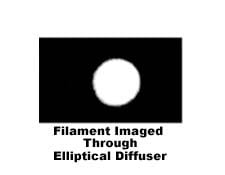

Holographic Diffusers are used to control the diffuse area of illumination and increase transmission efficiency to greater than 90% from filament lamps, LEDs, arc lamps, and other sources. Standard ground glass and opal glass will produce diffuse illumination, but the diffuse light area will often exceed the requirements of the system. This over-illumination, associated with traditional diffusers, reduces efficiency and can often lead to added costs by requiring higher power illumination sources, lenses, and possibly filters. It is important to note that diffusing angles are given for a collimated input beam and angular divergence will vary for different incidence angles.

Unlike many holographic elements, these specific polycarbonate components transmit light in both the visible and near-infrared. Zero order, or a specular component, of transmitted light is less than 1% for visible wavelengths, but may be higher if these diffusers are used at wavelengths >700nm. Available individually, as umounted sheets, or in sets of four filters. Holographic Diffusers can be cleaned with a de-ionized water rinse, followed by a forced air drying. Wipe gently with lens tissue soaked with methanol, followed with a forced clean air or nitrogen drying. Holographic Diffusers are resistant to methanol and methylene chloride.

Note: Matte surface should face the light source. To clean holographic diffusers, dampen a lint free cloth wipe with methanol and gently wipe the entire diffuser surface in a gentle, circular pattern. Immediately and carefully blow off the clean diffuser area with dry compressed air. Caution: cleaning may cause a change in the optical performance of the diffuser.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®