Acktar Light Absorbent Foil and Film is used to eliminate light reflectance in applications where the direct coating of parts is not practical, including optical packaging, laser devices and platforms, IR systems, or passive thermal control. Acktar Light Absorbent Foil and Film features high emissivity with low reflectance, low outgassing, excellent biocompatibility, a broad operating temperature range, and compatibility with class 1 cleanrooms. Acktar Light Absorbent Foil and Film is available in pre-cut patterns or as large sheets for custom patterns.

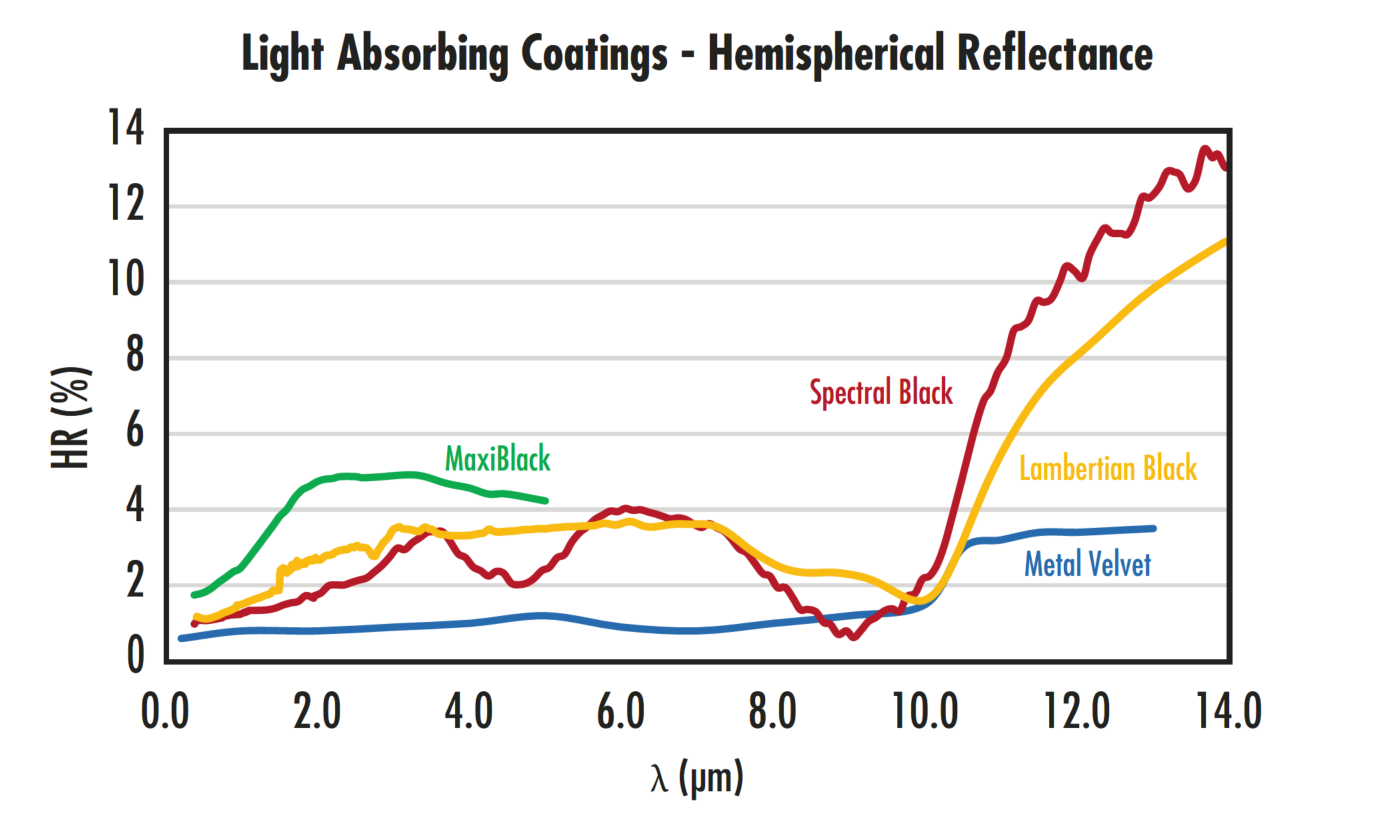

Acktar Light Absorbent Foil and Film is offered in Metal Velvet™ (diffusive coating on aluminum), Spectral Black™ (semi-specular coating on aluminum), MaxiBlack™ (diffusive coating on polyimide), or Lambertian Black™ (diffusive coating on stainless steel). Metal Velvet offers superior light absorption performance while Spectral Black is more durable, and Lambertian Black performs better at grazing angles. Maxiblack, in addition to being durable and flexible, is nonconductive and can be used in applications that require light absorbing materials with no electrical conductivity.

Note: Metal Velvet has low resistance to abrasion and all surface contact should be avoided without proper equipment.

| Product Type | Metal Velvet™ | Lambertian Black™ | MaxiBlack™ | Spectral Black™ | Hexa-Black™ |

| Key Features | Low reflectance of ~1% | High absorption at grazing angles | Thin polyimide, nonconductive substrate | Semi-specular finish | Ultra-high absorption at grazing angles |

| Substrate Material | Aluminum | Stainless Steel | Polyimide (Kapton) | Aluminum | Aluminum Honeycomb |

| Substrate Thickness | 120µm | 100µm | 75µm | 130µm | 2mm |

| Appearance | Diffusive | Highly Diffusive | Diffusive | Specular | Diffusive 3D Structure |

| Typical Spectral Range | EUV - FIR | EUV - FIR | UV - MWIR | VIS - MWIR | EUV - FIR |

| AOI Range | 0 - 60° | 0 - 80° | 0 - 60° | 0 - 45o | 0 - 88° |

| Reflectance @ 0° AOI | ~1% | ~1.5% | ~2.5% | ~2% | ~1.5% |

| Abrasion Resistance | Light | Moderate to High | Moderate | Moderate | Moderate |

| Cleanliness | Class 10000 - ISO 7 | Class 100 - ISO 5 | Class 100 - ISO 5 | Class 100 - ISO 5 | Class 10000 - ISO 7 |

Edmund Optics offers comprehensive custom manufacturing services for optical and imaging components tailored to your specific application requirements. Whether in the prototyping phase or preparing for full-scale production, we provide flexible solutions to meet your needs. Our experienced engineers are here to assist—from concept to completion.

Our capabilities include:

Learn more about our custom manufacturing capabilities or submit an inquiry here.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®