TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

TECHSPEC® components are designed, specified, or manufactured by Edmund Optics. Learn More

| Volume Pricing | |

|---|---|

| Qty 1-5 | S$247.92 each |

| Qty 6-25 | S$198.64 each |

| Qty 26-49 | S$186.69 each |

| Need More? | Request Quote |

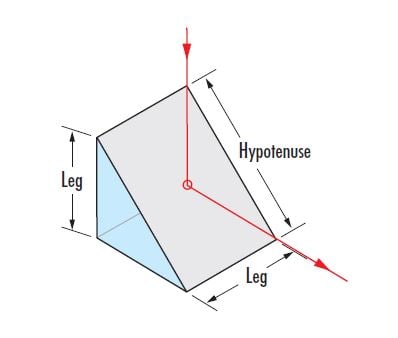

TECHSPEC® Broadband Dielectric Coated Right Angle Mirrors are designed for beam steering or precision alignment applications utilizing multiple laser sources or operating from the visible to near-infrared spectra. These mirrors feature improved reflection compared to standard metal coated mirrors, increasing system performance by decreasing energy loss. These right angle mirrors are easily mounted and integrated into optical systems. TECHSPEC® Broadband Dielectric Coated Right Angle Mirrors reflect light at 90º and have greater than 98% reflection over broad wavelength ranges. These mirrors feature a N-BK7 substrate and are available in a variety of leg lengths.

Note: These right angle mirrors are not recommended for use in applications where light is reflected off the coated hypotenuse from inside the prism.

Edmund Optics offers comprehensive custom manufacturing services for optical and imaging components tailored to your specific application requirements. Whether in the prototyping phase or preparing for full-scale production, we provide flexible solutions to meet your needs. Our experienced engineers are here to assist—from concept to completion.

Our capabilities include:

Learn more about our custom manufacturing capabilities or submit an inquiry here.

or view regional numbers

QUOTE TOOL

enter stock numbers to begin

Copyright 2024, Edmund Optics Singapore Pte. Ltd, 18 Woodlands Loop #04-00, Singapore 738100

California Consumer Privacy Acts (CCPA): Do Not Sell or Share My Personal Information

California Transparency in Supply Chains Act

The FUTURE Depends On Optics®